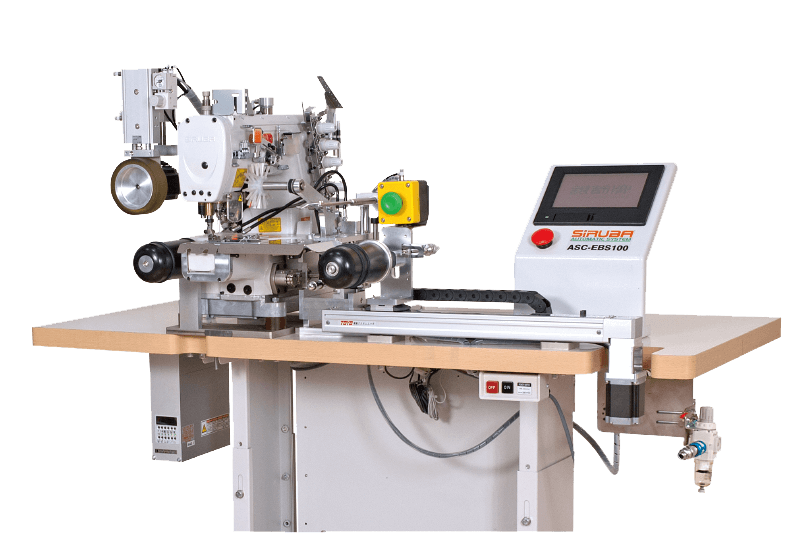

SIRUBA ASC-EBS100

SIRUBA ASC-EBS100 is a interlock stitch automatic machine for sewing the rubber into waistband.

A modern automatic machine dedicated for sewing rubber into waistband on a interlock machine – (the rubber must be previously sewn on overlock or ASK-EBS100 machine). The machine sews the rubber in a round/circle, ensuring regular tension around all perimeter of the waistband. The operator role is only to hem rubber, putting the prepared waistband on the tension rollers and starting the machine.

Uniform tension and mutual positioning of materials are controlled by a sensor system and do not require any intervention by the operator. Automatic chain cutting and foot lifting affect high quality and sewing performance. The machine uses a cylinder bed Siruba C007KD head.

The ease of use and high level of automation mean that the operator can operate up to two machines at the same time, which significantly affects the speed and efficiency of work (preparation time and sewing one rubber in the waistband about 10 seconds assuming stitching parameters: number of stitches: 385, stitch length: 3,8 – 4.0 mm, sewing speed: 4000 stitches / min). Control via an easy-to-use and legible touch control panel.

Technical parameters:

- sewing speed 4000 stitches / min

- width of sewn rubber 20 – 40 mm

- circumference of rubber tension rollers 940 – 1600 mm

- UY128GAS # 10 needles

- working pressure 0.5 MPa

- 230V power supply

Compressed air connection required (capacity min 150L / min).